- Home

- Industries

- Slaughter Line

- Pork

Pork Equipment

Pork is the culinary name for the meat of the domestic pig. Pork is eaten both freshly cooked and preserved. Curing extends the shelf life of the pork products. Humane handling and stunning of pigs is essential for a high quality end product. RGMTSI offers a broad stunning program of CO2 stunners ensuring the highest animal welfare handling as well as a range of captive bolt stunners for emergency slaughtering. Ergonomic shackling using the RGMTSI shackling device takes the strain off the operators. With a high grade blood collection system, customers can benefit from an additional revenue stream.

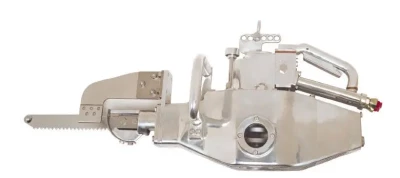

Spinal Cord Sheath and Mis Split Remover

SHC 165G spinal cord and mis-split remover for beef or pork.

Spinal Cord Sheath and Mis Split Remover

- Latest patented technology for grinding away BSE risk material, including the spinal cord, which is under the mis-split, and the meninges (spinal cord).

- Connected to a vacuum system that collects removed spinal cord material for disposal.

- Lightweight, powerful (2.5 hp) hydraulic motor – no bogging down or motor icing; low noise and instant stop.

- Heavy duty gears made to withstand the extreme conditions found in larger meat processing plants.

- Rugged construction provides unsurpassed durability.

- Meets national and international requirements for hygiene and safety.

Meat Tenderizer

Meat Tenderizer is one of the most important components in the production of boneless cooked products such as ham, shoulder, chicken or other meats. A conveyor feeds product to a set of rollers equipped with circular knives. This effectively increases the meat surface and opens the muscle tissue, boosting liquid retention and promoting higher concentration of protein at the surface after massaging. The rollers are designed for easy sanitation and do not need to be disassembled to clean the knives.

Meat Tenderizer

- Used for boneless cuts of pork, beef, chicken, or turkey

- Increases the absorption capacity of meat by opening muscle fibers and exposing inner meat surfaces.

- Increases the quantity of muscle protein on meat surfaces for further processing.

- Rollers equipped with circular knives.

- Accommodates product up to 3-1/8" (80 mm) thick.

- Open design of knife roller for easy sanitation.

- Optional hopper for loading product onto conveyor.

Brisket Saw

Hydraulic powered brisket saws for beef, hog splitting and forequartering.

Brisket Saw

- The powerful MG-1 cuts through all beef briskets quickly and easily. The high performance MG-1B is even faster, suitable for kills over 200 beef / hour. Models MG-1HS and MG-1BHS are ideal for hog splitting and hog brisket cutting. Model MG-1BFQ is the perfect saw for forequartering.

- The MG-1 and MG-1HS cuts fat cattle briskets in 5 seconds, the MG-1B, MG-1BHS and MG-1BFQS in 3 seconds.

- Small and maneuverable for optimum handling.

- A balanced drive system makes all MG-1 models smooth and quiet for less operator fatigue.

- Minimal maintenance due to the oil bath lubricated drive and no electrical components.

- Meets international requirements for safety and hygiene. USDA and CE approved.

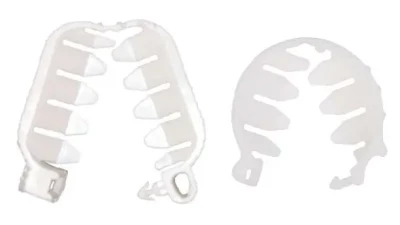

Weasand Clips

for sealing the esophagus of slaughtered stock.

Weasand Clips

- Weasand clips are designed for sealing the esophagus of slaughtered beef and sheep.

- Made of plastic in the U.S.A.

- Designed to keep the esophagus sealed tightly during processing procedures.

- Shipped in clear plastic bags for optimum hygiene and convenience.

- Beef: Available in white, blue and black

- Also available: Rodder for beef and Rodder for sheep

Spinal Cord Removal System

SR-1 vacuum system for spinal cord removal on beef or hogs.

Spinal Cord Removal System

- Increases shelf life.

- Fast – one operator can handle 800 hog or 350 beef carcasses per hour.

- Lightweight handpiece for optimum operator comfort.

- High vacuum ensures that operator traces spinal cavity only once to remove the cord.

- All stainless steel construction for maximum hygiene.

- Hardened nozzle tip for better scraping action.

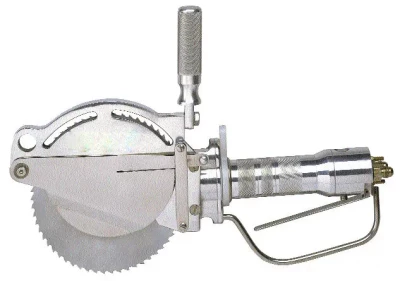

Hydraulic Circular Saw

SHC 140 and SHC 165 hydraulic powered general purpose breaking saws.

Hydraulic Circular Saw

- The right or left handed SHC140, with a 1.5 in (38 mm) cutting depth, or SHC 165 with a 2 in (51 mm) cutting depth are ideally suited for:

- Beef: Breaking forequarter and beef plates, also hot and cold ribbing.

- Pork: Ham and shoulder marking, ribbing and chine bone removal

- Lightweight with hydraulic power – no bogging down, no motor icing, low noise, and instant stop.

- Heavy duty gears made to withstand all uses in the packing plant industry.

- Rugged, corrosion resistant construction for optimum hygiene.

- New style USDA approved blade guard for easy internal sanitation.

- Lever style adjustable depth gauge for precise depth control cutting.

- Instant blade stop.

- Meets national and international requirements for hygiene and safety.

Head Dropper

3HD hydraulically powered hog or beef head dropper.

Head Dropper

- The 3HD quickly and easily severs the head from butcher hogs, sows, boars and beef.

- Fast – a single operator can handle up to 1200 hogs / hour.

- Designed for optimum handling and maneuverability.

- Robust stainless steel construction, including solid stainless steel blades and single piece clevis for best possible hygiene and low maintenance.

- Greasable pivot points for extended life.

- Anti-tie down controls for operator safety.

- Meets national and international requirements for safety and hygiene.

Chitterlings Cutter

HCC-1 hydraulically powered chitterlings cutter.

Chitterlings Cutter

- The HCC-1 is specifically suited to cut the intestines of beef, hogs and sheep.

- Flexible – cuts the intestine any desired length.

- Accurate – mechanically controls the length of cut.

- Quick and easy blade change.

- Constructed from all stainless steel for easy cleaning and optimum hygiene.

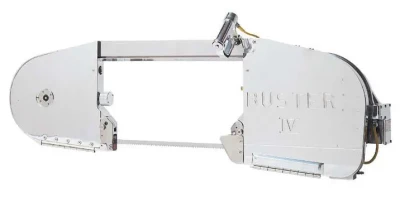

Buster IV Carcass Splitting Bandsaw

Buster IV electrically powered bandsaw for splitting cattle, pigs and sows.

Buster IV Carcass Splitting Bandsaw

- Used in all major U.S. plants for splitting fat cattle (800 – 1050 lbs / 360 – 480 kg).

- Smaller and better handling for optimum performance in the most demanding applications (up to 180 beef / hour / saw).

- Superior blade life: 400 – 600 carcasses per blade.

- Best possible hygiene – spoked wheels, flat surfaced housings and completely opening doors – for fast, easy and complete cleaning.

- The drive system is oil bath lubricated for sustained trouble-free operation.

- Designed for the operator – ultra-thin rail for unobstructed vision and dual rear handles for comfort.

- Anti-tie down controls and totally enclosed electric motor for operator safety.

- Meets national and international requirements for hygiene and safety.

Breaking Circular Saw

1000-FS – hydraulically powered breaking saw.

Breaking Circular Saw

- The 1000-FS, with a 3 to 6.0 in (76 to 152mm) depth of cut, is ideally suited for:

- Beef: chucks, shoulders, ribs, forequarters, chine bones, briskets, loins and aitch bones.

- Pork: chine bones and ham marking.

- High powered hydraulic motor – no bogging down, no motor icing, low noise and instant stop.

- Anti-tie down controls for operator safety.

- Constructed from corrosion resistant materials for optimum hygiene.

- Meets national and international requirements for safety and hygiene.