- Home

- Industries

- Food

- Cheese

Cheese Equipment

Cheese is a dairy product, derived from milk and produced in wide ranges of flavors, textures and forms by coagulation of the milk protein casein. It comprises proteins and fat from milk, usually the milk of cows, buffalo, goats, or sheep. Reduce production time and optimize production yield with RGMTSI cheese production equipment.

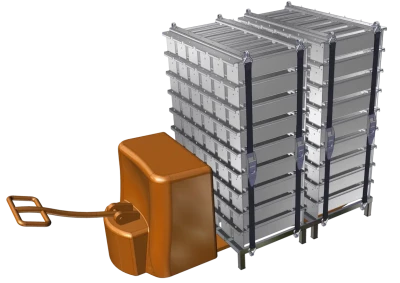

Kit Multimolds

The patented Multimolds kits are design to shape meat products for customers using other cooking and chilling technologies than the Thermix system. The Multimolds kits are used in different applications in the food processing industry.

Kit Multimolds

- The patented Multimolds kits are a 100% stainless steel custom design molds that guarantees total flexibility in products shapes.

- Optimum product shape consistency with accurate dimensions thanks to constant positive interlocks

- Uniform cooking thanks to specifically designed channels for the circulation of the heat transfer fluids

- Optimum hygienic conditions thanks to its sanitary design

- Custom made Multimolds to suit each customer’s need

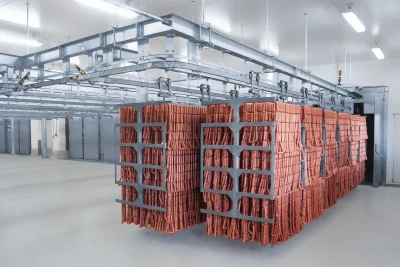

Industrial Rooms for CMP

CMP is short for Continuous Maturing Process and represents our continuous maturation system. With this technology, we distinguish ourselves from all other systems through shorter processing times, product uniformity combined with increased product capacity. This unique system is able to perform the maturing and drying process without any breaks. Due to the control of relative humidity and temperature for inlet and outlet air, it is possible to dry products without any variation. The system is able to move the air continuously (100% of the time) without any rest period.

Industrial Rooms for CMP

- Complete consistency means less than 1% deviation in the entire processing room

- Saving up to 30% processing time

- Significant energy savings

- Optimal utilisation of footprint and room height with full trolley loading up to 6 m in height

- Up to 250% more product can be produced in the same footprint than with comparable systems.

Industrial thawing systems ATA

The optimal system for balanced thawing without much weight loss. This thawing system has the best prerequisites for consistent quality in the subsequent processes.

Industrial thawing systems ATA

- Consistent thawing with high loading capacity

- Variable: The customer can supply the processing room from insulated panels or insulated brickwork.

- Minimum energy consumption: The system’s energy supply is chosen so that the target values can be rapidly achieved. All thawing processes can be controlled and regulated via the operating temperature, the core temperature or the peripheral temperature.

- Environmentally friendly: Minimum energy consumption: Individual air circulation systems and fresh air / exhaust air controls for each trolley place considerably reduce process times and thus energy requirements. Each trolley place is processed at the same temperature and relative humidity.

AllroundSystem ASR

The flexible and space-saving system solution for smoking and cooking. From smouldering and friction to liquid smoke – the customer has the choice. Due to the AllroundSystem, the production possibilities are virtually unlimited.

AllroundSystem ASR

- Wide variety of flavours and colours: Various external and internal smoke generation systems such as smouldering smoke, condensate smoke, friction smoke or liquid smoke, are available for smoking.

- Efficiency: The strongest air circulation guarantees consistent product quality with minimum weight loss during drying and smoking despite maximum trolley loading.

- Minimum space requirement: Individually tailored solutions can be developed for both larger industrial or smaller trade companies thanks to the system’s exceedingly small width and height dimensions. Building investment costs are reduced considerably.

ProfitLine PRR

ProfitLine systems are universal allrounders due to the horizontal and vertical air circulation, regardless whether products are placed horizontally on mesh shelves or suspended on smokesticks. The enormous air circulation allows for uniform product quality with the least weight loss.

ProfitLine PRR

- Wide variety of flavours and colours: All external and various internal smoke generation systems, such as smouldering smoke, condensate smoke, friction smoke or liquid smoke, are available for smoking.

- Efficiency: Due to two fans an extensive air circulation guarantees constant product quality with minimum weight loss upon drying and smoking despite maximum trolley loading.

- Designed for industry: The central air conditioning system incorporates all required equipment such as a heat exchanger, a central circulation fan, an air alternating damper, fresh air and smoke supplies and a mixing chamber for air conditioning.

- Minimum energy consumption: Individual air circulation and optimal use of fresh air energy during drying enormously reduce your process times and thus the energy requirements. The system as well as the air handling unit are fully insulated.

Semi continuous batch system KCS

The production process takes place continuously in a continuous batch system; from filling to packaging, there is no delay in the processing of products.

Semi continuous batch system KCS

- “Inline” production: The production process is performed inline with the semicontinuous loading system, i. e. there is no processing delay between filling and packaging.

- 100% Separation between low and high risk areas: The airtight transfer zone between the entry and exit sides allows the separation of production and packaging areas (“low-risk“, “high-risk“).

- Integration: The system can be integrated into the production area due to upstream and downstream automation.

CORR VAC Mark III

Modified Atmosphere Packaging, also known as M.A.P. packaging equipment. Preserves, protects and extends the shelf life of your products. Whether it is individual bags, lined cases, bulk-bin, totes, Gaylords, barrel, or super-sacks, RGMTSI has a proven solution.

CORR VAC Mark III

- 100% stainless steel and FSMA, FDA, & USDA compliant. Optional 3A dairy-grade

- Always ready for wash-down as we build-to IP69 specifications assuring IP67 compliance

- Seal bars available include either 30, 54, 62, and 100-inch lengths

- Vacuum pump standard or optional liquid-ring and venturi

- Hot-bar or impulse sealing

- Bag-stretcher option to insure wrinkle free bags

- Optional two hand controls

- Flexible probes reduces damage and extends life

- A variety of language options on our simple to understand controller

- Floor mount, optional casters, or unit can hang over conveyor.

- Gas flush any product that degrades in atmosphere

- Multi-gas flush totes or super-sacks of organic products assuring inserts and larvae are asphyxiated.

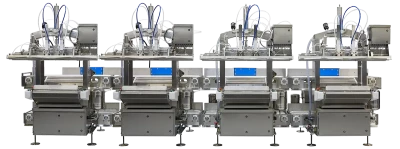

Mark III mHSP MAP Machine

Presenting the 3rd generation multi-station incorporating all of the features our customers have requested over the years while providing the safest, most sanitary and well thought out M.A.P. packaging machine of its kind on the market. Available in 2, 3, 4 or more stations allowing for unprecedented flexibility and now with higher Modified Atmosphere Packaging speeds. Each module includes its own infeed as well as outfeed belt. Start with 2 or three stations and easily add a 4th module in minutes as they interface and communicate by simply connecting a water-tight cable.

Mark III mHSP MAP Machine

- You thought there was a placeholder text here, but it was me DIO!

A200 Bin Modified Atmosphere Packaging Machine

The A-200 Bin Machine line brings the advantages of Modified Atmosphere Packaging to large and bulk items. Full pallets and bins can now be processed efficiently. Wrinkle free seals are achieved with seal bars up to 100 inches (2540mm) and automatic bag stretchers or clamps. Floating head prevents bag pullout.

A200 Bin Modified Atmosphere Packaging Machine

- You thought there was a placeholder text here, but it was me DIO!

CORR VAC MAP VAC

This Modified Atmosphere Packaging Machine has a 1355 mm (53.5-inch) seal-bar, polished, engineered not to bend or distort providing unprecedented and repeatable seal pressure. Wrinkles and gussets are no longer an issue, the MAP-Vac simply seals through them. Twin Teflon gas-flush / vacuum probes at 9.25” or 15 inch spacing opens easily and can be 100% sanitized

CORR VAC MAP VAC

- Twice the seal. Introducing a first of its kind Dual-Pinch, Dual-Seal, hot bar sealing system with cooledge technology. No other M.A.P. machine offers such a wide seal surface area.

- The Corr-Vac MAP-Vac has retractable bag stretchers for quick access for ease of use.

- The B & R model C30 TFT full-color 7” power-panel touch screen offers 4/8 program capability.

- By pressing both cycle buttons simultaneously, the operator's hands are out of the way of the closing seal bar