- Home

- Industries

- Food

- Hot Dog

Hot Dog Equipment

A hot dog is a dish consisting of a grilled or steamed sausage served in the slit of a partially sliced bun. The term hot dog can also refer to the sausage itself. The sausage used is a wiener or a frankfurter. The names of these sausages also commonly refer to their assembled dish. Optimize your yield production with RGMTSI hot dog processing equipment. Reduce production time while maintaining consistent quality of your hot dogs.

Camatix Pasteurization

The Camatix is fully continuous Sous Vide in-package pasteurization or cooking system that allows processors to produce best quality meals for consumers who demand clean label products. In package thermal pasteurization has become the most reliable and cost effective method for guaranteeing safe RTE products with little or no antimicrobial ingredients to stabilize pathogenic bacteria.

Camatix Pasteurization

- A continuous carousel product handling system with automated, multi-level loading and unloading cages, ensuring high capacity throughput into a reduced footprint.

- Different successive agitated water processing tanks for: cooking/pasteurizing, and chilling are custom configured for the packaged products.

- Synchronized with multiple packing machines, the Camatix system works continuously at a steady pace of 2 to 5 tons per hour. Its pass through design delivers a constant flow of superior-quality products.

- The products are organized in the outfeed of the Camatix replicating the position they had in the infeed.

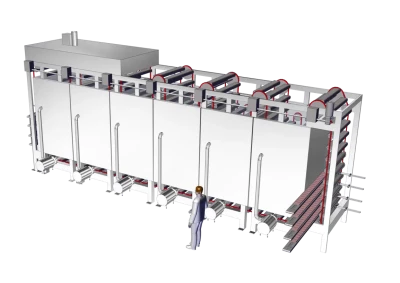

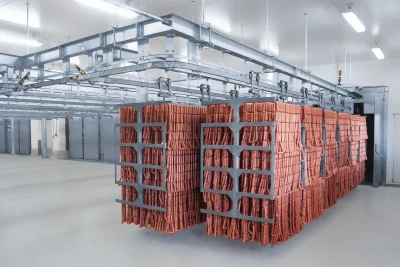

Industrial Rooms for CMP

CMP is short for Continuous Maturing Process and represents our continuous maturation system. With this technology, we distinguish ourselves from all other systems through shorter processing times, product uniformity combined with increased product capacity. This unique system is able to perform the maturing and drying process without any breaks. Due to the control of relative humidity and temperature for inlet and outlet air, it is possible to dry products without any variation. The system is able to move the air continuously (100% of the time) without any rest period.

Industrial Rooms for CMP

- Complete consistency means less than 1% deviation in the entire processing room

- Saving up to 30% processing time

- Significant energy savings

- Optimal utilisation of footprint and room height with full trolley loading up to 6 m in height

- Up to 250% more product can be produced in the same footprint than with comparable systems.

Industrial thawing systems ATA

The optimal system for balanced thawing without much weight loss. This thawing system has the best prerequisites for consistent quality in the subsequent processes.

Industrial thawing systems ATA

- Consistent thawing with high loading capacity

- Variable: The customer can supply the processing room from insulated panels or insulated brickwork.

- Minimum energy consumption: The system’s energy supply is chosen so that the target values can be rapidly achieved. All thawing processes can be controlled and regulated via the operating temperature, the core temperature or the peripheral temperature.

- Environmentally friendly: Minimum energy consumption: Individual air circulation systems and fresh air / exhaust air controls for each trolley place considerably reduce process times and thus energy requirements. Each trolley place is processed at the same temperature and relative humidity.

AllroundSystem ASR

The flexible and space-saving system solution for smoking and cooking. From smouldering and friction to liquid smoke – the customer has the choice. Due to the AllroundSystem, the production possibilities are virtually unlimited.

AllroundSystem ASR

- Wide variety of flavours and colours: Various external and internal smoke generation systems such as smouldering smoke, condensate smoke, friction smoke or liquid smoke, are available for smoking.

- Efficiency: The strongest air circulation guarantees consistent product quality with minimum weight loss during drying and smoking despite maximum trolley loading.

- Minimum space requirement: Individually tailored solutions can be developed for both larger industrial or smaller trade companies thanks to the system’s exceedingly small width and height dimensions. Building investment costs are reduced considerably.

ProfitLine PRR

ProfitLine systems are universal allrounders due to the horizontal and vertical air circulation, regardless whether products are placed horizontally on mesh shelves or suspended on smokesticks. The enormous air circulation allows for uniform product quality with the least weight loss.

ProfitLine PRR

- Wide variety of flavours and colours: All external and various internal smoke generation systems, such as smouldering smoke, condensate smoke, friction smoke or liquid smoke, are available for smoking.

- Efficiency: Due to two fans an extensive air circulation guarantees constant product quality with minimum weight loss upon drying and smoking despite maximum trolley loading.

- Designed for industry: The central air conditioning system incorporates all required equipment such as a heat exchanger, a central circulation fan, an air alternating damper, fresh air and smoke supplies and a mixing chamber for air conditioning.

- Minimum energy consumption: Individual air circulation and optimal use of fresh air energy during drying enormously reduce your process times and thus the energy requirements. The system as well as the air handling unit are fully insulated.

Semi continuous batch system KCS

The production process takes place continuously in a continuous batch system; from filling to packaging, there is no delay in the processing of products.

Semi continuous batch system KCS

- “Inline” production: The production process is performed inline with the semicontinuous loading system, i. e. there is no processing delay between filling and packaging.

- 100% Separation between low and high risk areas: The airtight transfer zone between the entry and exit sides allows the separation of production and packaging areas (“low-risk“, “high-risk“).

- Integration: The system can be integrated into the production area due to upstream and downstream automation.

Universal circulation system KK

Especially developed for these processes, these systems are efficient in the processing of products and can be customized as a solution for industry and craft.

Universal circulation system KK

- Low investment costs: The systems are specially developed for the cooking process in order to guarantee low investment costs for a high production capacity.

- Efficiency: The optional air circulation system guarantees excellent product flexibility so that e.g. ham can be produced in various moulds despite high trolley loading.

- Minimum space requirement: Individually tailored solutions can be developed for both larger industrial or smaller trade companies thanks to the system’s exceedingly small width and height dimensions. Building investment costs are reduced considerably.

Steam inject circulation cooking system SKU

Space-saving and cost-effective: thanks to its slim dimensions, this cooking system is the perfect solution for every craft and industrial company.

Steam inject circulation cooking system SKU

- Low investment costs: The systems are specially developed for the cooking process in order to guarantee low investment costs for a high production capacity.

- High product quality: A consistent and reproducible product quality with low process costs is achieved thanks to the technically sophisticated direct steam injection system in the cabinet.

- Efficiency: The air circulation guarantees a high product flexibility.

- Minimum space requirement: Individually tailored solutions can be developed for both larger industrial or smaller trade companies thanks to the system’s exceedingly small width and height dimensions. Building investment costs are reduced considerably.

ProfitLine PK

Cooking with low investment costs and high production capacities? Guaranteed by ProfitLine PK.

ProfitLine PK

- Low investment costs: The systems are specially developed for the cooking process in order to guarantee low investment costs for a high production capacity.

- High product quality: A consistent and reproducible product quality with low process costs is achieved thanks to the technically sophisticated direct steam injection system in the cabinet.

- Designed for industry: Wide door opening clearance.

Cooking kettles FK

An energy-saving and universally applicable solution for all cooking processes in different installation variations.

Cooking kettles FK

- Simple and effective cooking: The modern control of the cooking kettles fulfils everything that is required. The control is easy to handle and shows the set target performance comparison at any time. It saves the programs until a new program is entered. It offers broad alternatives of any kind of control system.

- Delta-t-cooking with the kettle: With the technology of RGMTSI sensitive quality products such as cooked ham can be produced without any problems.

- Valuable investment: The interior of the kettle is manufactured of stainless steel (1.4571 / AISI 316). This guarantees a highest possible corrosion resistance and thus a long economic life time.

- Low energy consumption: Outstanding heat retention is one feature of kettles. Electrically heated kettles have optimal heat transfer to the cooked products.