- Home

- Industries

- Food

- Beverage

Beverage Equipment

A drink is a liquid intended for human consumption. In addition to their basic function of satisfying thirst, drinks play important roles in human culture. Common types of drinks include plain drinking water, milk, juice and soft drinks. Traditionally warm beverages include coffee, tea, and hot chocolate. We provide high-quality beverage manufacturing equipment. From filtration equipment, carbonation, sugar dissolvers, blenders, mixers and heat exchangers.

PrimeMove Belt Conveyor

Reliable material handling is a critical part of overall manufacturing process. That is why Belt Conveyors are custom-made to meet your demanding production requirements. Choose from a multitude of belt widths, drive speeds, and belt styles. Optional casters allow portability. Sanitation and cleanability are just as important. Drain-through or solid interlocking belts, quick release take-ups, washdown duty motors, and removable sides and wear strips make the CBC series a standalone among other belt conveyor designs.

PrimeMove Belt Conveyor

- Horizontal, inclined, turning, or in-line metal detector style conveyors in custom sizes.

- Horizontal feed and discharge options available.

- Choice of hydraulic or electric drive.

- Hinged or removable sides.

- Quick-release take-up design raises belt for easy cleaning of conveyor bed and belt.

- Variety of sanitary bearing designs available.

- Wide range of belt designs: solid, interlocking and wire.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

Diverters for loaded and empty pallets

The corner diverters for pallets are made with a roller and chain system ; they are used to make 90 ° movements on roller conveyors and to move the load between one roller conveyor and another. The diverter for roller and chain pallets consists of a roller conveyor and a chain conveyor, placed at right angles to each other, which allow the pallet’s axis of advancement to be changed by 90°. The chain conveyor, at the junction point with the roller conveyor, tilts with a vertical movement, allowing the palletised load to pass from one conveyor to another.

Diverters for loaded and empty pallets

- Thanks to a modular design, the diverters that we produce are able to satisfy all requirements in terms of size, configuration and speed dictated by the customer.

- The sectors of use include the food and beverage industry, the chemical and pharmaceutical industry and logistics.

- The machines for industrial handling and automatic industrial handling systems are studied and designed by us in order to optimise the work flow, the customer’s production requirements and the structural needs of the building.

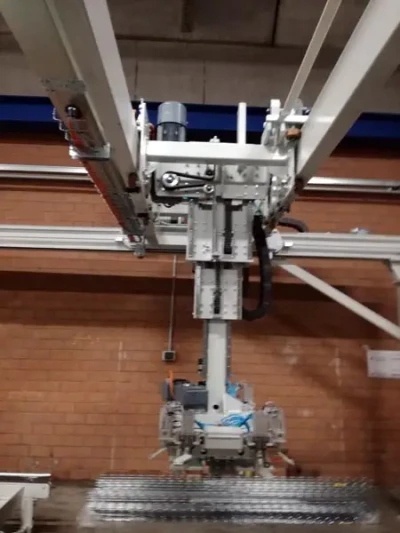

Cartesian telescopic palletisers

The Cartesian telescopic palletiser has been designed for those who, in small spaces, need to make the work of loading, arranging and stacking products on pallets automatic, quick and safe. The system can handle bags, flexible bags, cartons, boxes, drums, bottles and any kind of item that is positioned and aligned on the pallets thanks to the multi-axis system with special customised grippers. The palletisers we have created allow us to optimise business efficiencies, saving time and money as, thanks to these tools, the constant supervision of operators involved in the palletising and storing of goods is unnecessary. An automatic palletiser ensures the supply of all the incoming and outgoing movements of the product to be palletised, management of the positioning of the interlayer, the handling of empty pallets and the transportation of full pallets. The classic modular structure can be extended, according to requirements, to create palletising lines at multiple stations with various picking points being served.

Cartesian telescopic palletisers

- Sturdiness, versatility and ease of use

- The Cartesian palletiser is programmed via PLC and this allows optimisation of the work cycles as required.

- Palletising takes place through the pick & place method, picking up the product individually or not and depositing it on the pallet according to the programmed scheme.

- The vertical telescopic arm allows the use of various types of gripping modules and allows positioning of the packs also in high containers, such as carton-boxes, pallet-boxes and octabins.

- The electronics used allow the creation of any type of layer, while the easy-to-use management software allows even the less experienced operators to quickly change the work program and even to modify the palletising scheme to adapt it to various requirements.