- Home

- Industries

- Food

- Ice Cream

Ice Cream Equipment

Ice cream is a sweetened frozen food typically eaten as a snack or dessert. It may be made from dairy milk or cream and is flavoured with a sweetener, either sugar or an alternative, and a spice, such as cocoa or vanilla, or with fruit such as strawberries or peaches. RGMTSI's ice cream processing equipment includes mix pasteurization plants, ageing tanks, continuous freezers, ingredient feeders / ripple pumps, ice cream filling machines, stick ice cream moulding and wrapping machines as well as ice crushing machines. We are the right partner for medium and large scale ice cream producers: innovative development, simplicity in operation and maintenance, excellent performance in terms of return on investment (ROI).

Arctic C

ARCTIC C are container pre-assembled automatic extrusion lines for small and medium size productions.

Arctic C

- Capacity range: from 3.000 to 10.000 pcs/hour

- Products: sticks, ball cones, sandwiches, wafer cups

TDSF Twin Drum Spiral Freezer

The Twin Drum Spiral Freezer (SFT) is the perfect solution for freezing of large capacities of packaged products like ice cream and dairy products, as well as delicate products that require gentle transport. The in- and out-feeds are both on the same floor level.

TDSF Twin Drum Spiral Freezer

- Belt width up to 1500 mm

- Product height as per request

- Steel or plastic spiral belt

- Non-stacking spiral belt for heavy product load

- Optional: Sequential defrosting of evaporators

- Can be adapted to suit almost any processing line

- Capable of running with heavy products (high belt load)

- Horizontal airflow for quick freezing and reduced product dehydration

- Maximum utilization of the spiral belt, as no air has to pass through the belt

- In-feed and out-feed in the same pressure zone

- No need for floor heating

- Multiple drive motors

- Recipe-controlled for easy operation

- Flexible design with multiple layout options

- Manufactured in stainless steel with open profiles for easier cleaning

SDSF Single Drum Spiral Freezer

Designed for medium-large capacity processing lines with belt width up to 1500 mm, the Single Drum Spiral Freezer (SDSF) is suitable for almost any processing line. Extra strong belt supports makes it possible to carry heavy products demanding a long retention time. The spiral freezer is the most flexible spiral solution and can be adapted to fit almost any processing line.

SDSF Single Drum Spiral Freezer

- Belt width up to 1500 mm

- Product height as per request

- Steel or plastic spiral belt

- Non-stacking spiral belt for heavy product load

- Optional: Sequential defrosting of evaporators

- Can be adapted to suit almost any processing line

- Capable of running with heavy products (high belt load)

- Horizontal airflow for quick freezing and reduced product dehydration

- Maximum utilization of the spiral belt, as no air has to pass through the belt

- In-feed and out-feed in the same pressure zone

- No need for floor heating

- Multiple drive motors

- Recipe-controlled for easy operation

- Flexible design with multiple layout options

- Manufactured in stainless steel with open profiles for easier cleaning

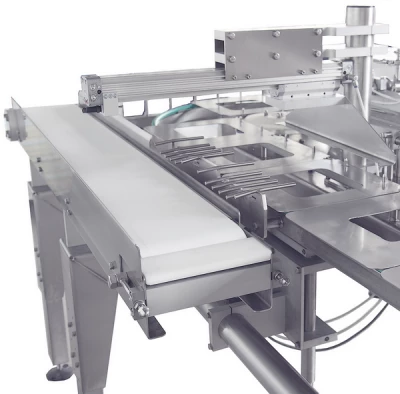

Arctic EX / CX

ARCTIC EX, CX are custom built lines for medium and large scale productions.

Arctic EX / CX

- Products: complete range of products made by extrusion systems

- Capacity range: from 6.000 to 18.000 pcs/hour

Arctic M

ARCTIC M are smallest line from range of ARCTIC C lines, ideal start for family business.

Arctic M

- Capacity range: from 3.000 to 4.000 pcs/hour

- Products: choco dipped sticks, funny face sticks, water ice sticks, ball cones, sandwiches, logs

Worktable W1 / W2

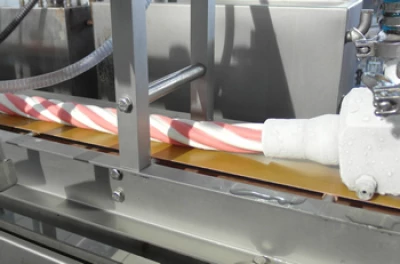

W1 / W2 are flexible independent attachments to extrusion lines, capable of producing of wide range of inovative, sophisticated products.

Worktable W1 / W2

- Conveyor with belt speed regulation, product transfer unit, pneumatically operated

- PLC unit to synchronize the worktable with extrusion line, incl. encoder

- Cutting station, heated, temperature control

- Capacities 3 500 pcs/hour (W1) and 7 000 pcs/hour (W2) are available

- Typical products made: Multilayer stick products, Rotated stick products, Bar stick products, Special stick products

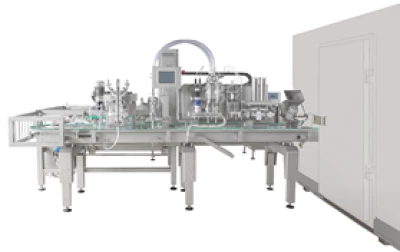

LF Filling Machine

LF-04/06/08 semiautomatic filling machine for cups & cones have

LF Filling Machine

- Max diameter of cup is 90mm

- Strong stainless steel frame with adjustable legs

- Set of lamellas with 4/6/8 holes for plastic holders (one type of holder included)

- Step-by-step pneumatic/servo lamella drive

- Electronic control panel in IP 65 protection rate, made od AISI 316 stainless steel with electric elements and controls

- Operator panel 8\" LCD touch screen. Screens and labels in English/local language

- Filling station made of 4/6/8 time-elapse filling heads, single color, with adjustable filling volume. Vertical movement of filling station on pneudrive (servodrive on request).

- Lifting station on outlet, for easy discharge of finished products.

- Central PLC computer OMRON

- Pneumatic components FESTO

WT Filling Machine

WT series are semiautomatic filling machines with high flexibility

WT Filling Machine

- Large variety of ice cream products: cones, cups, containers, bulk and cakes.

- All product settings stored in PLC

- Easy change-over between products

- Open design

- Strong stainless steel frame with adjustable legs

- Operator panel 8\" LCD touch screen. Screens and labels in English/local language

- Step-by-step movement of trays by servodrive

- Filling station made of 1/2/4/8 time-elapse filling head/s. Vertical movement of filling station on servodrive

- Pencil filler

- Topink decoration

- Product discharge belt

DU Filling Machine

Stand-alone filler designed for filling ice cream semi-automatically with or without inclusions into “family bulk” containers - rectangular, square or round, or ice cream decorated cakes. It can operate both with ice-cream or with creamy products. It is completely made of stainless steel and of anodized light alloy. Every part that comes into contact with the product is made of materials according to the current sanitary and hygienic lows. It works electro pneumatically.

DU Filling Machine

- Supporting framework.

- Time filler with pneumatic cylinder.

- Control electric panel. Panel and labels in English/local language.

- Control filling cylinder.

- Working table.

- Pressure reduction gear filter unit.

- Working table adjusting clamps.

- Filler vertical translation. servomotor and detachment.

- Connections to product to be filled with variegation (syrup).

- Pneumatic components FESTO.

Mix HTST

MIX HTST has the compact and hygienic stainless steel design. The space requirements are minimalised by means of optimal layout of the plant. The plant is easy to operate, all parts and components are easy to inspect and maintain.

Mix HTST

- Mixing tank (2 pcs), double speed stirrer, temperature indication

- Mix filter

- Centrifugal pump to deliver the mix to the balance tank

- Balance tank with floater

- Centrifugal pump to deliver the mix to the heat exchanger

- Plate heat exchanger, 4 section

- Homogenizer with pumping pistons, working pressure 180 bar, single stage

- Tubular holding unit

- Control panel with all electricals, temperature display, liter counter display

- Liter counter to measure amount of water going to mixing tank, according to the recipe

- Boiler supply hot water for the pasteurizing section of plate heat exchanger. The hot water can be prepared through electricity/gas or steam

- Centrifugal pump to deliver the hot water to the heat exchanger

- Optional accessories: High pressure plate exchanger for viscous, special mixes, Powder feeder for dry ingredients, Weighing system, Fat melting tank, Chilled water tank, Second homogenizing stage, PLC control, automation and optimisation of the process, Visualization of the process, Temperature registration.