Spray Drying Equipment

Spray drying is a method of producing a dry powder from a liquid or slurry by rapidly drying with a hot gas. This is the preferred method of drying of many thermally-sensitive materials such as foods and pharmaceuticals, or materials which may require extremely consistent, fine, particle size.

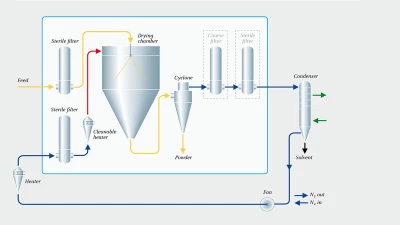

Aseptic Spray Dryer

For decades, spray drying has been applied for powder production by the pharmaceutical industry – also under aseptic conditions. The Aseptic Spray Dryer is perfect for the production of sterile pharmaceutical products such as vaccines, antibiotics and other products requiring aseptic conditions. A precise control of the drying process gives far greater command over the shape, density and morphology of the final product than other aseptic drying technology, and moreover, with low running and capital costs, these advantages are obtained while reducing overheads. Production of dry sterile dosage forms often involves mixing of the API with one or more excipients. To achieve a homogeneous mixture, the particle size distribution of the excipient(s) must match that of the API. In a one-step-operation, aseptic spray drying can turn a sterile solution into sterile particles of the required size with no risk of introducing impurities. The spray dryers are also designed for handling organic solvents, which makes possible the use of a wide range of excipients within the formulation.

Aseptic Spray Dryer

- You thought there was a placeholder text here, but it was me DIO!