Packaging Equipment

Once dosage form is in its final form, it must be properly packaged for distribution. Packaging can also come in different forms which determines how products are handled.

Ampoule and Vial Blister Cartoning Line

Ampoule and Vial Blister Cartoning Line offers a perfect solution for ampoules and vials packaging. Featuring robust robotic system, the Ampoule and Vial Blister Cartoning Line aims to improve and optimize efficiency at every stage in the blister packaging process. With an optional YAMAHA 4 or ABB 6 robot feeders, expect accurate and consistent blister cavity feeding and sealing. This blister cartoning line adopts an independent PLC with advanced touchscreen HMI, while the electrical systems are mainly OMRON, SMC or Leybold. The modular design and easy part changeover makes it easy to adopt Ampoule and Vial Blister Cartoning Line for a range of ampoules and vials packaging. To ensure safety, all moving parts and processing sections of blister packing line feature a safety cover with an auto stop mechanism. The Ampoule and Vial Blister Cartoning Line also features a stainless steel structure, as per the cGMP requirements, with a robust and stable structure. Easy to clean surface with virtually no dead angle meets the hygienic requirements in the pharmaceutical and food processing industries. Ampoule and Vial Blister Cartoning Line can be customized for specific pharmaceutical needs.

Ampoule and Vial Blister Cartoning Line

- Max output: 300 -400 ampoules/minute; 160-240bottles/minute

- Fully integrates machine with blister packaging and cartoning machine

Syringe Blister Cartoning Line

Syringe Blister Cartoning Line is specially designed for syringe and vials mixed packing. It is a syringe blister cartoning line featuring sturdy structure and optimized for domestic packaging. With ABB robot feeders, easy to integrate strapping and carton packer, Syringe Blister Cartoning Line improves the blister packing efficiency and accuracy. It is a cGMP compliant machine, with a PLC control system and touchscreen HMI, for easy operation and adjusting system parameters. The frequency control drive and servo motor ensure precise control of motion, for accurate blister packaging of syringes. Syringe Blister Cartoning Line also has a camera for feeding detection, blister forming detection and "lack of material" testing systems.

Syringe Blister Cartoning Line

- Production capacity: Up to 200syringes/min

- Maximum carton size: 70-200*35-85*14-85mm

- Weight: 5000kg

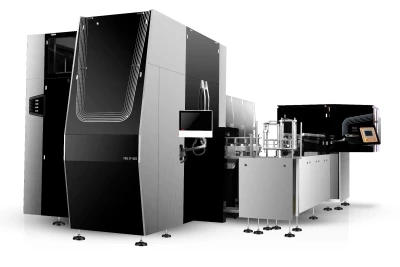

Blow Fill Seal Machine

BFS (Blow-Fill-Seal) system is innovative technique which is capable of blow molding, aseptically filling, and sealing in one continuous operation. A direct-blow molding technology is incorporated with the time pressure-enhanced filling machine that allows forming the containers and filling solutions simultaneously. Extrusion: The plastic tube extruded from the granules is fed into the opened blow mold. Moulding: The main mold closes, sealing the base in the process. The mandrel is lowered onto the neck of the mold and uses compressed air to blow the tube section into the container shape. Small containers are molded with a vacuum. Filling: The container is filled with the precise product amount as measured by the dosing system, again via the mandrel. Sealing: The mandrel is removed, the head mold closes, and the required closure is formed by a vacuum. Demoulding: The blow mold opens, the container leaves the machine, and the next cycle begins. A conveyor system takes the container to the next processing stage.

Blow Fill Seal Machine

- Shatterproof plastic containers

- Ideal for the aseptic filling of liquids and gels

- Maximum safety due to ISO Class 5 conditions at the filling point

- Officially recognized as an advanced aseptic system

- Fully automatic manufacture, filling, and sealing in a single process

- Maximum process and product reliability

- Maximum filling precision

- Virtually unlimited scope in terms of container design

- Customizable to different uses and dosage forms

- Modular design for easy separation of gray and white system zones

Wash Sterilize Fill Seal Line

Vial Wash-Dry-Fill-Seal Production Line is used the washing, sterilization, filling and sealing of small volume vial injection in workshop. It features advanced design, reasonable structure, high degree of automation, stable and reliable operation, high production efficiency and mechanical and electrical integration. The parts contacted with drug liquid are made of AISI316L and the other are made of AISI304. The materials used have no pollution on drug and environment.

Wash Sterilize Fill Seal Line

- Vial specification: 1ml-100ml

- Output capacity: 10-500 vials / minute

- Filling accuracy: ≤±1%

- Ultrasonic washing + Water-Air alternating washing

- Brands of core components: SIEMENS, GEMU, FESTO, ABB, Schneider, etc.

- The overall design and manufacturing are in line with FDA and the new GMP.

- Vial Wash-Dry-Fill-Seal Production Line is composed of Vertical Ultrasonic Washing Machine, Drying and Sterilization Oven, and Vial Fill-Seal Machine. It features coordination interaction, stepless speed regulation and accurate control and can meet production process requirements.

- It features high production speed, high qualification rate, no impact, no wrong action, no squeezing and on broken vials.

- It is equipped with various safety devices to ensure the safety of the operator and machine.

- Validation ports are reserved on main parts.

- It features PLC control, touch screen operation and programmed production.

- Buffer devices are installed on the connection point between three units of the production line, thus able to ensure reliable and stable operation.

- It has the function of no bottle no filling.

- It has centralized oil supply system which can easily add oil on lubrication points.

Injection Moulding And Blowing System

The Injection Moulding And Blowing System is mainly used for making the empty bottle from the PP granule. Including the Injection Molding Machine and Bottle Blowing Machine.

Injection Moulding And Blowing System

- Bottle embryo in and out system: The bottle embryo conveying, discharging and feeding device can automatically detect the number of bottle embryos, realize the automatic switching of the action on and off, and reduce the energy consumption.

- Heating system: The infrared lamp tube is used for heating embryos, so that uniform stretch, high transparency, short heating time, low energy consumption, high output capacity can be realized. The temperature of each lamp tube in each layer can be independently adjusted. According to the difference of the embryos, each lamp tube can make front-back and left-right adjustment (marked with a graduated scale).

- The high-precision temperature control system can accurately control the heating temperature of each point of the embryos and feedback accurate temperature signal, thus able to improve the forming rate of the bottle and reduce the material and energy consumption.

- Blowing system: The system is simple and reliable. The embryos are heated uniformly. The bottleneck is not hot. The service life of lamp tube is long. A cooling water channel is arranged below the heating chamber, and the cooling water channel is used for blocking the heat of the lamp tube when the embryos are heated so as to protect bottleneck from deformation. Chilled water can rapidly decrease mold temperature.

- Manipulator driven by servo has simple structure and reliable performance and can accurately convey embryos rapidly.

- The embryo feeding manipulators and bottle taking manipulators are arranged separately, so that the machine moves more flexibly, runs more stably, and shortens the bottle blowing operation period.

- Servo stretching system is used to control the stretching speed and stroke accurately and make the bottle wall shape uniform. Stretching position can be preset so that that bottom is symmetrical. When the bottle type is changed, the stretching adjustment can be completed on the touch screen, and the operation is simple and convenient. Pre-blowing and blowing cycle time can be adjusted.

- More than one emergency stop buttons are provided in order to ensure timely shutdown in case of failure. There is machine running position monitoring function and when operation is not in place or failure occurs, alarm is generated and machine shut down automatically and waits for inspection. PLC is used to monitor running status at any time. It can diagnosis machine failure point and give the cause of the failure.

Pharma Form Fill Seal Line

Non-PVC bag Pharma Form-Fill-Seal Line line (FFS Line) is composed of bag forming section, filling-sealing station, control cabinet and laminar flew hood. Available for: Multi-Chamber IV Injection Bags; 3-Chamber Infusion Bags; Double Chamber IV Injection Bags; Double Chamber Infusion Bags; Powder Liquid Double Chamber Infusion Bags; Single Hard Port Infusion Bags; SPT Port Infusion Bags; SFC Port Infusion Bags; Double Soft Tube Infusion Bags.

Pharma Form Fill Seal Line

- You thought there was a placeholder text here, but it was me DIO!